Performance characteristics

This kind of product is a lotion polymerized by polyvinyl acetate and a variety of polymer modified materials, with durable internal plasticization and flexibility. The product complies with Japanese F ☆☆☆☆ and European E0 standards, with strong adhesion and fast drying speed. It is suitable for bonding various substrates, has a good hand feel, is elastic, water-resistant, acid and alkali resistant, high temperature resistant, no organic pollution, and does not affect human health, safety, and environmental protection.

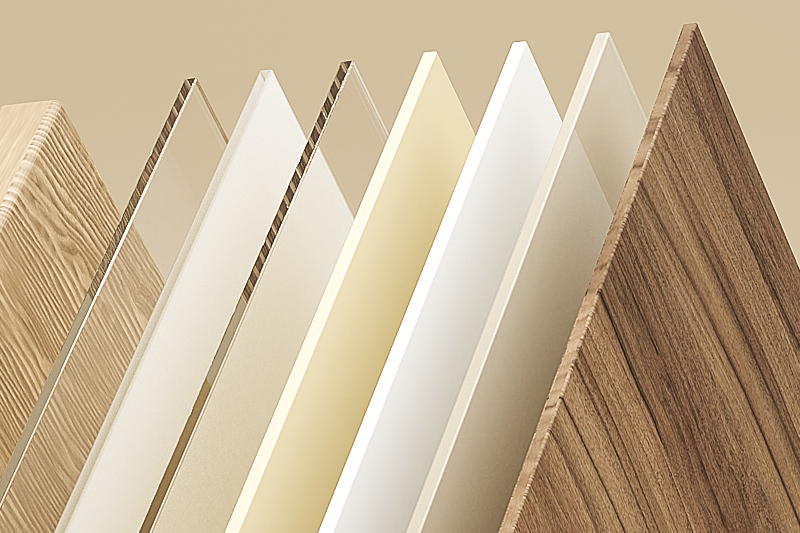

scope of application

This type of product is mainly used for wood finger joints, honeycomb interlayers, EVA materials, plywood, fireproof board composites, melamine boards, and the bonding between wood veneer and wood. Heating and curing can improve water resistance, and it is most suitable for mechanical gluing. It can also be operated manually with an electric iron.

Construction methods and precautions

1、 Firstly, clean the surface treatment of the adhesive, evenly apply glue to the surface of the adhesive (machine or hand applied glue amount is 250-300/M2), bond and press the two surfaces tightly. Use clips, tape or heavy objects to gently press both sides of the adhesive, with a pressure of 5-7KG/CM2 and a pressure time of 1.5-2 hours. The next process can be carried out (hot pressing for 3-5 minutes). For adhesive under pressure, the pressurization time should be correspondingly extended.

2、 The viscosity (consistency) of the adhesive can be adjusted appropriately according to the user's requirements.

3、 When using adhesive, please do not add water to the adhesive, otherwise it will affect the bonding strength.

4、 When using glue in areas with high humidity and low temperature, the drying time will be correspondingly extended. Please extend the pressurization time appropriately.

The product performance and application data are obtained from practical experience and laboratory experiments, and are only for users to consider when selecting products and operations. However, considering that there are many factors such as pressure, wood moisture content, flatness, etc. that cannot be controlled by our company in the actual operation process, it is recommended that users conduct small sample tests according to the instructions before use to ensure the suitability of the product for their specific use.